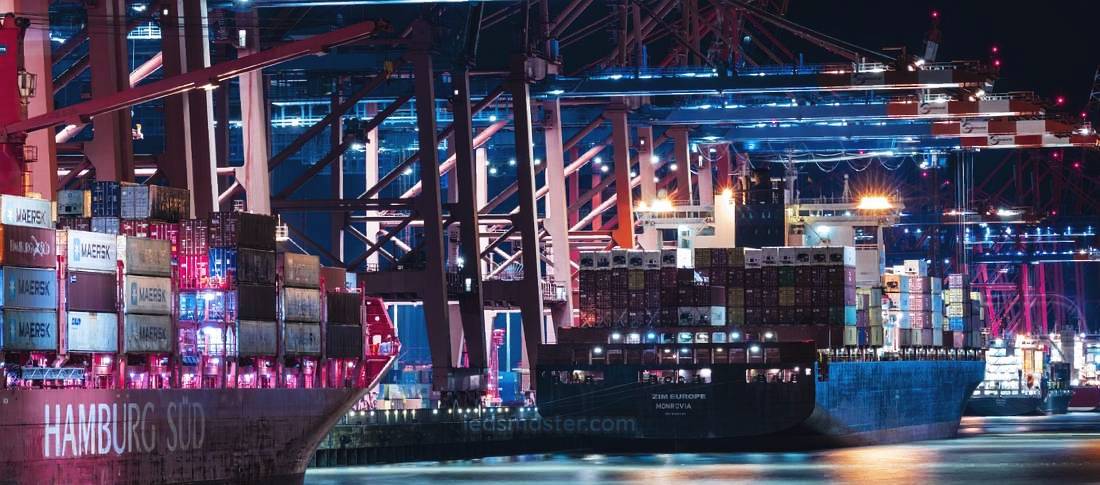

Container ports are bustling hubs where every detail matters for smooth operations. Picture the complexity of managing countless containers under the right lighting conditions. Explore how these towering fixtures are key to creating a well-lit and operationally effective port environment.

Get your complimentary lighting design today

Properly designed and strategically placed, these light poles contribute significantly to the smooth functioning of port operations, addressing challenges such as harsh environmental conditions, high operational demands, and rigorous safety and regulatory standards.

Table of Contents

Toggle

The coastal environments where container ports are typically situated expose light poles to various harsh conditions, including saltwater, humidity, and strong winds. These elements can quickly degrade materials, leading to rust, corrosion, and reduced operational lifespan if not properly addressed. To withstand such environments, light poles are often constructed from corrosion-resistant materials like stainless steel or aluminum. These metals are less reactive to salt and moisture, ensuring longer durability.

In addition to the choice of materials, protective coatings are applied to the surface of light poles. These coatings create a barrier against environmental factors, helping to reduce the impact of salt spray, which can corrode metal surfaces over time. Poles are also designed to resist wind loads. In regions prone to high winds, the structural integrity of light poles must be assessed to ensure they remain upright and stable, even during storms. Wind-resistant designs help prevent the poles from swaying or vibrating, which could lead to damage.

Designing light poles with these environmental considerations reduces long-term maintenance needs. Less frequent repairs or replacements result in fewer interruptions to port operations, enhancing overall efficiency.

In a busy port, inadequate lighting coverage can lead to unsafe conditions for workers and slow down container handling operations. Light poles are generally designed to be tall enough to illuminate large areas, with heights ranging from 20 to 50 meters or more, depending on the layout of the port and the areas requiring illumination.

Higher poles provide a wider spread of light, which means fewer poles may be needed to cover a given area. However, higher light poles also come with increased wind exposure, so they need to be designed with wind-resistant features to avoid instability. Strategic placement of the poles is also necessary to avoid dark spots, which can impair visibility and pose risks during container handling or vehicle movement. Careful planning ensures uniform illumination across critical areas such as loading docks, container storage zones, and access roads.

Shadows and glare can reduce visibility, even with well-placed lighting. When positioning light poles in container ports, planners must ensure that shadows created by stacked containers, cranes, and other large structures are minimized. Shadows can cause blind spots for crane operators, forklift drivers, and security personnel, which may increase the likelihood of accidents or security breaches. Proper placement of light poles, along with appropriate use of high-quality lighting fixtures, helps minimize the occurrence of shadows and ensures smooth, uninterrupted operations.

Similarly, glare is a common issue in outdoor lighting, particularly in areas with reflective surfaces like water, metal containers, and vehicles. Excessive glare can make it difficult for operators to see clearly, especially when working at night or in foggy conditions. Lighting designers often use specialized fixtures and shields to reduce glare, improving the overall visibility within the port without compromising the effectiveness of the lighting.

The uniform distribution of light across a container port is vital to maintaining operational flow and safety. Poorly distributed lighting can result in bright spots and dark zones, where visibility is compromised. Uniform lighting helps ensure that workers have a clear view of their surroundings, which reduces the potential for accidents during operations such as container loading, unloading, and transfer. This is particularly beneficial in high-traffic areas where equipment and personnel are in constant motion.

The selection of fixtures that provide consistent light distribution across broad areas is a key factor in achieving uniformity. Wide-angle light distribution is often preferred in container ports, as it spreads light over larger distances without leaving gaps in coverage. Light fixtures installed on tall poles must be calibrated to deliver even light levels, ensuring that both near and far zones receive adequate illumination.

Brightness levels in a container port must be sufficient to facilitate safe operations at all times. The measurement of brightness is often described in terms of lux levels, which indicate the amount of light output in a given area. For container ports, recommended lux levels vary depending on the specific areas being lit. General yard areas where containers are stored may require lower lux levels, while more critical zones such as entry points, loading docks, and workstations demand higher levels to ensure visibility.

Lux levels are usually guided by industry standards, which recommend specific brightness levels for outdoor industrial and commercial spaces. Maintaining the appropriate lux levels contributes to safer working conditions, enabling workers to identify potential hazards and operate machinery effectively, even at night or during poor weather.

Lighting systems in container ports are subject to various regulatory standards and guidelines that ensure the safety, efficiency, and environmental compliance of the installation. These standards often vary by country or region, but they typically provide benchmarks for lighting performance, fixture placement, brightness levels, and environmental impact. Ports must comply with these regulations to operate legally and efficiently.

In many regions, international standards such as those developed by the Illuminating Engineering Society (IES) or the International Maritime Organization (IMO) set the guidelines for outdoor lighting in industrial zones like ports. These guidelines specify the lux levels required for different operational areas, taking into account factors such as worker safety and operational efficiency.

Compliance with regulatory standards is a necessary consideration when designing lighting systems for container ports. It ensures that the port meets safety requirements, reduces the risk of accidents, and avoids potential legal penalties. Moreover, ports that adhere to these standards are often seen as safer and more reliable, which can have a positive effect on their reputation among shipping companies and port workers.

Apart from general lighting standards, container ports must also comply with safety and environmental regulations that govern the impact of artificial lighting on the surrounding environment. These regulations may address issues such as light pollution, energy efficiency, and the impact of lighting on local wildlife. For example, ports near coastal areas often have restrictions in place to reduce light pollution, which can disrupt marine ecosystems or interfere with nearby residential areas.

To meet these requirements, lighting systems must be designed with the environment in mind. This may include using fixtures that reduce light spillage beyond the port boundaries or installing dimming systems that lower light levels during off-peak hours. Ports may also be required to submit environmental impact assessments for their lighting systems, ensuring that the design takes into account the long-term effects on the surrounding area.

Light poles in container ports are often subject to heavy loads due to their height and the weight of the fixtures they support. To ensure they remain secure and upright, the foundation of each pole must be carefully designed and constructed. The foundation must account for the specific environmental conditions at the port, including soil stability, wind loads, and the weight of the poles themselves.

In areas prone to strong winds, the stability of the light poles is especially critical. A strong foundation can help prevent poles from swaying or collapsing during storms, reducing the risk of damage to the lighting system and nearby equipment. Engineers often conduct detailed assessments of the port’s soil conditions before installation to determine the type and depth of foundation required for each pole. Proper installation practices also play a role in ensuring that light poles remain stable over time.

The harsh conditions of container ports require regular inspections and maintenance of light poles to ensure they remain functional and safe. Saltwater exposure, strong winds, and heavy operational use can lead to wear and tear on the poles and fixtures. Without proper maintenance, poles may corrode, light fixtures may fail, and the overall safety of the port could be compromised.

Preventative maintenance involves periodic inspections of the light poles, checking for signs of rust, corrosion, structural damage, and electrical issues. Regular cleaning of the poles and fixtures can also help prevent the buildup of salt and debris, which may accelerate the degradation of the materials. Replacing faulty parts before they fail entirely helps minimize downtime, ensuring that the port remains well-lit and fully operational.

Maintenance teams must also ensure that the lighting systems comply with evolving safety and environmental regulations. This can involve retrofitting older systems with newer, compliant technologies or upgrading light fixtures to meet the latest performance standards. A well-maintained lighting system contributes to the long-term safety and efficiency of the container port.

One of the primary functions of light poles in container ports is to provide adequate visibility for workers and equipment operators. Without proper lighting, tasks such as loading and unloading containers, operating cranes, and navigating vehicles become far more difficult and dangerous. Adequate lighting ensures that workers can see clearly at all times, reducing the likelihood of accidents and injuries.

In particular, crane operators rely heavily on clear visibility when maneuvering large containers. Properly placed light poles illuminate the work area, allowing operators to accurately position containers on ships or in storage yards. Adequate lighting also helps security personnel monitor the port, especially in areas that may be prone to unauthorized access or theft.

Security is a major concern in container ports, as these facilities often handle high-value cargo. Light poles contribute to overall port security by illuminating key areas such as entry gates, perimeter fences, and storage yards. By combining lighting systems with surveillance technologies, such as CCTV cameras, ports can enhance their ability to monitor activity and respond to potential security threats.

In many cases, security cameras are mounted directly on light poles, taking advantage of the height and coverage provided by the poles. Well-lit areas allow for clearer video footage, making it easier for security personnel to identify and track individuals or vehicles within the port. Lighting systems can also be integrated with motion detectors or automated controls, which adjust the light levels based on real-time activity within the port. This ensures that areas of the port are always well-lit when needed, further enhancing the security of the facility.

Effective lighting not only helps prevent accidents but also serves as a deterrent against theft, vandalism, and unauthorized access. A well-illuminated port is easier to monitor and maintain, contributing to the overall safety and security of the operation.

By selecting durable, corrosion-resistant materials and ensuring proper placement to avoid shadows and glare, ports can provide consistent lighting that enhances visibility and supports efficient operations. Compliance with regulatory standards ensures that lighting systems meet both safety and environmental requirements. Regular maintenance further contributes to the longevity of the system, reducing operational downtime and ensuring that the port remains a well-lit, secure environment for workers, equipment, and cargo. Through proper planning and upkeep, light poles serve as a vital element in the overall success of container port operations.