Discover efficient and resilient lighting solutions tailored for rail yards, ensuring optimal visibility and safety amidst dynamic operational environments.

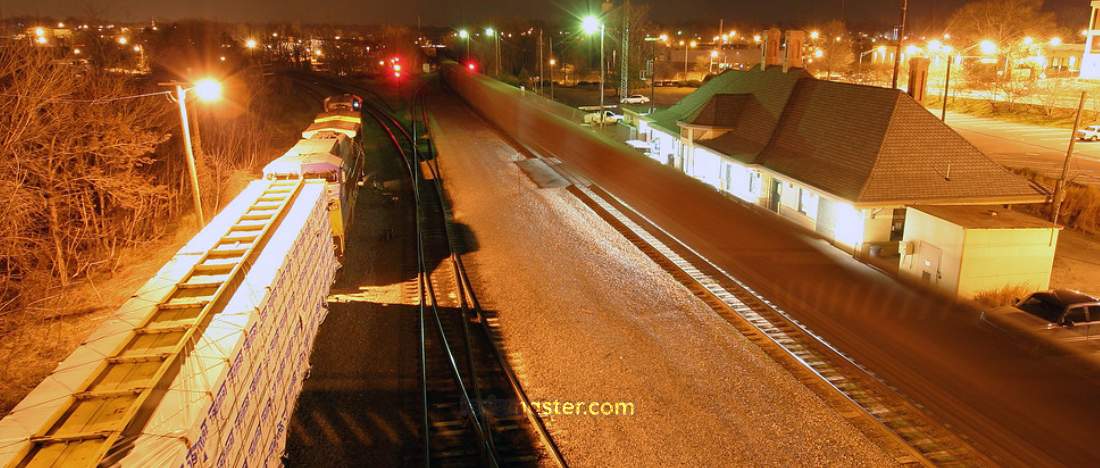

Rail yards are pivotal to the transportation industry, serving as hubs for the assembly, maintenance, and storage of freight and passenger trains. Efficient lighting within these expansive environments is crucial for ensuring operational continuity, enhancing safety, and maintaining security.

Get your complimentary lighting design today

Table of Contents

ToggleThe functionality of rail yards hinges on continuous, effective lighting. These facilities operate around the clock, necessitating illumination that supports a wide range of activities. Adequate lighting enhances visibility for workers performing tasks such as train assembly, maintenance inspections, and cargo handling. It also facilitates efficient surveillance and security measures, crucial for monitoring activities across the vast expanse of rail yards.

Consistent lighting across operational zones—such as storage tracks, inspection pits, and access roads—minimizes shadows and glare. Shadows can obstruct visibility, posing safety risks and impacting the operational flow of activities. By strategically positioning lighting fixtures at specific heights and angles, rail yards achieve comprehensive illumination, which is crucial for safe and efficient operations. Uniform lighting minimizes the likelihood of accidents and reduces the risk of operational delays, allowing workers to perform their duties with greater accuracy and confidence.

Consistent lighting across operational zones—such as storage tracks, inspection pits, and access roads—minimizes shadows and glare. Shadows can obstruct visibility, posing safety risks and impacting the operational flow of activities. By strategically positioning lighting fixtures at specific heights and angles, rail yards achieve comprehensive illumination, which is crucial for safe and efficient operations. Uniform lighting minimizes the likelihood of accidents and reduces the risk of operational delays, allowing workers to perform their duties with greater accuracy and confidence.

Designing for uniformity also takes into account the diverse lighting needs of different areas within the rail yard. Storage tracks, where trains are parked and maneuvered, require high-intensity lighting to guide trains safely to their designated spots. Inspection pits and access points benefit from angled lighting to illuminate working surfaces and avoid glare. By implementing uniform, high-coverage lighting, rail yards create an environment that fosters seamless workflow, enhancing both productivity and safety.

The required lighting levels in rail yards are governed by industry regulations to ensure operational safety. Specific standards dictate the levels of illuminance necessary to provide workers with optimal visibility in various areas, which is especially important given the complexity and demands of rail yard tasks. LED lighting is widely recognized as the ideal choice for these settings due to its ability to deliver high-quality, uniform light while consuming minimal energy. LEDs provide substantial cost savings over traditional lighting options, like halogen or incandescent bulbs, and are less prone to frequent replacement. This reduces both operational costs and the environmental impact of rail yard lighting.

LEDs also help rail yards maintain consistent lighting levels across large spaces, which is crucial for operational efficiency. Bright, even lighting provided by LEDs improves visibility, which reduces error rates and enhances productivity. LED technology’s longevity and low maintenance needs make it a sustainable lighting solution that aligns with the modern rail yard’s goals for efficiency and reliability.

Rail yards are environments of constant mechanical activity, with trains, heavy machinery, and workers moving continuously. This activity generates constant vibrations that can impact the durability and functionality of standard lighting fixtures. To counter this challenge, rail yard lighting systems are designed with shockproof features that enable them to withstand these mechanical stresses. Shockproof fixtures are typically constructed with robust materials and are built to absorb vibrations without impacting functionality.

These specialized lighting fixtures reduce the need for frequent replacements and maintenance, ensuring the lighting system remains dependable. Shockproof lighting thus contributes significantly to the resilience of rail yard operations, providing a durable solution that withstands the unique demands of the environment. As a result, lighting systems can maintain uninterrupted service, supporting safe and efficient operations even under challenging conditions.

Rail yards are typically open-air facilities exposed to a variety of weather conditions, including rain, snow, humidity, and extreme temperatures. Lighting fixtures in these settings must be constructed from durable materials capable of withstanding the elements. Common materials used for these fixtures include aluminum alloys, stainless steel, and polycarbonate, which are corrosion-resistant and do not degrade easily under UV exposure. This durability ensures that rail yard lighting systems remain functional and require minimal maintenance, reducing both downtime and associated operational costs.

Weatherproof seals and gaskets are crucial for protecting lighting fixtures from environmental contaminants such as moisture and dust. These seals prevent water from penetrating the internal components, preserving the electrical integrity of the fixtures. Moreover, corrosion-resistant coatings add an extra layer of protection against rust, enhancing the overall lifespan of the lighting system.

High-intensity LED lights are often positioned along the tracks to provide clear, focused visibility, which is vital for precise train movements and parking. Properly illuminated tracks reduce the risk of accidents or derailments, creating a safer environment for both workers and machinery. Track lighting also supports logistics operations, ensuring that trains can be moved quickly and efficiently to their designated positions, reducing delays and enhancing productivity.

Track lighting design often includes directional LED lights to target specific areas of the rail, ensuring maximum visibility where it is most needed. The focused, bright illumination provided by LED track lighting not only aids in the accurate movement of trains but also facilitates smoother logistics operations, contributing to overall operational efficiency and safety.

Lighting for maintenance areas, such as inspection pits, workshops, and repair bays, demands a flexible approach. Mechanics and technicians working in these areas require bright, adjustable lighting that allows them to inspect trains thoroughly and perform detailed repairs. Flexible lighting solutions, with adjustable angles and intensity, ensure that workers have the precise level of light they need for tasks requiring high accuracy. These lighting setups minimize shadows and allow technicians to work efficiently, enhancing both safety and productivity.

In maintenance areas, adjustable lighting fixtures are often installed to provide optimal illumination, regardless of the position or angle of the worker. High-quality lighting in these areas is crucial for minimizing the chances of oversight during repairs or inspections, which can have significant implications for rail yard safety and efficiency. This precise illumination ultimately contributes to the overall effectiveness of maintenance operations and the reliability of the rail yard.

LED technology has been transformative for rail yard lighting, bringing substantial energy savings and supporting environmental sustainability goals. LEDs consume considerably less energy than traditional lighting sources, which reduces operational costs while providing higher quality and more durable light. LEDs have longer lifespans than conventional lighting options, leading to reduced maintenance needs and fewer replacements. This durability not only cuts down on costs but also aligns with sustainable practices by minimizing waste.

LED lighting also offers environmental benefits, as it produces lower carbon emissions compared to other lighting technologies. By adopting LED lighting, rail yards can achieve their sustainability objectives, contributing to a reduction in overall energy consumption and aligning with global goals for a cleaner environment. This focus on sustainable lighting technology also supports the rail yard’s long-term operational goals, helping to meet the evolving demands of modern transportation and logistics networks.

The integration of motion sensors and automated lighting controls has become an increasingly valuable tool for enhancing energy efficiency in rail yards. Motion sensors detect human activity, adjusting lighting levels in response to occupancy or movement within certain zones. This targeted lighting approach ensures that only occupied areas are illuminated, reducing unnecessary energy consumption and contributing to overall operational cost savings.

Automated controls offer the additional benefit of scheduling and remote monitoring capabilities. Lighting schedules can be programmed to ensure that lighting is turned on or off at specific times, optimizing energy usage. Furthermore, remote monitoring allows rail yard managers to oversee lighting performance and make adjustments as needed. This combination of motion sensors and automated controls creates an adaptive lighting system that enhances both energy efficiency and safety standards in rail yards.

By prioritizing shockproof design, durability, and energy-efficient technologies such as LED lighting, rail yards can enhance visibility, reduce operational costs, and mitigate environmental impact. Implementing these best practices not only improves overall performance and safety but also strengthens the resilience of rail yard operations in the face of diverse operational challenges. By investing in advanced lighting solutions, rail yards can foster a safer, more efficient transportation network that meets the demands of modern logistics and enhances overall industry productivity.