High mast flood lights provide extensive illumination for spaces such as stadiums, highways, airports, and industrial zones. These lighting systems are designed to be elevated on tall poles, sometimes reaching heights of up to 30 meters or more. Given their height, high mast flood lights are exposed to various environmental factors, with wind load being one of the most significant. Understanding wind load factors is crucial for ensuring the structural integrity, safety, and long-term performance of these lighting systems.

Table of Contents

ToggleWhat is Wind Load?

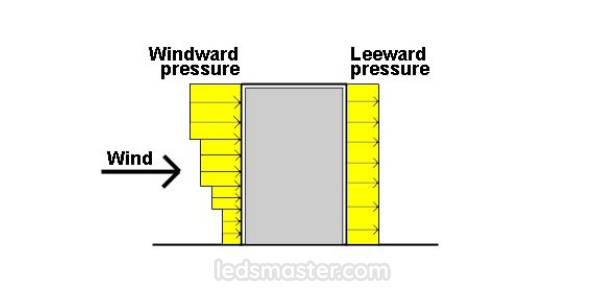

Wind load refers to the force exerted by the wind on a structure. In the context of high mast flood lights, wind load is the pressure or force that the wind applies to the flood light fixtures and the pole supporting them. This force can have a substantial impact on the stability and durability of the lighting system. Wind load is a critical consideration in the design, installation, and maintenance of high mast flood lights, as it directly affects their ability to withstand environmental stresses.

Wind load refers to the force exerted by the wind on a structure. In the context of high mast flood lights, wind load is the pressure or force that the wind applies to the flood light fixtures and the pole supporting them. This force can have a substantial impact on the stability and durability of the lighting system. Wind load is a critical consideration in the design, installation, and maintenance of high mast flood lights, as it directly affects their ability to withstand environmental stresses.

Ignoring wind load factors can lead to catastrophic failures, such as the toppling of the mast, damage to the lighting fixtures, or even accidents that could pose risks to people and property. Engineers and designers must account for wind load when selecting materials, determining the appropriate pole height, and choosing the design of the flood lights. Proper assessment of wind load ensures that the high mast flood lights can resist wind forces without compromising their functionality or safety.

Wind Load Factors for High Mast Flood Lights

Several factors influence the wind load on high mast flood lights. These factors include the angle of the wind, the shape and size of the flood lights, the height of the mast, and the geographical location of the installation. Understanding these factors helps in the accurate calculation and management of wind load.

Angle of Wind

The angle at which the wind hits the flood light fixtures plays a crucial role in determining the wind load. Wind can approach the structure from different angles, and each angle exerts a varying amount of force on the high mast flood lights. When wind hits the structure head-on (perpendicular), it exerts the maximum pressure, as the entire surface area of the light fixtures and the pole is exposed to the wind. However, when the wind approaches at an angle, the effective surface area exposed to the wind reduces, resulting in a lower wind load.

Designers must consider the most likely wind directions for the installation site to ensure that the high mast flood lights can withstand the maximum possible wind load. This consideration often leads to the implementation of measures such as the aerodynamic shaping of fixtures or the strategic orientation of the lights to minimize wind resistance.

Shape and Size of High Mast Flood Lights

The shape and size of the flood lights significantly impact the wind load they experience. Larger fixtures present a greater surface area to the wind, resulting in higher wind loads. Similarly, the shape of the lights influences how wind flows around them. Flat or broad surfaces tend to experience higher wind resistance, while streamlined or rounded designs can help reduce wind load by allowing air to flow more smoothly around the structure.

For example, rectangular flood lights with flat surfaces will experience higher wind loads than flood lights with a more aerodynamic design. Engineers often choose shapes that minimize wind resistance to ensure that the lighting system remains stable under high wind conditions.

Height of the Mast

The height of the mast on which the flood lights are mounted is another critical factor in wind load calculations. Wind speed increases with height, meaning that taller masts are subjected to stronger winds. As a result, the wind load on high mast flood lights increases as the height of the mast increases.

This relationship between height and wind load necessitates careful consideration when determining the appropriate height for high mast flood lights. Taller masts may require more robust construction materials, additional bracing, or even the use of guy wires to ensure stability. In some cases, it may be necessary to reduce the height of the mast to mitigate wind load and ensure the safety of the installation.

Geographical Location and Wind Zone

The geographical location of the installation site plays a significant role in determining the wind load on high mast flood lights. Different regions experience varying wind speeds and weather conditions, which can influence the wind load on structures. Wind zones are typically classified based on historical wind speed data, and these classifications help engineers determine the appropriate design standards for high mast flood lights.

For instance, coastal areas or regions prone to hurricanes or typhoons will experience much higher wind loads compared to inland areas with milder weather conditions. Engineers must account for the specific wind zone of the installation site when designing and selecting high mast flood lights to ensure that they can withstand the highest possible wind speeds for that region.

Materials and Construction for Wind Load Resistance

To effectively resist wind loads, high mast flood lights must be constructed using materials and designs that provide adequate strength and durability. The choice of materials, the design of the mast, and the mounting method of the flood lights all contribute to the system’s ability to withstand wind forces.

Material Selection

The materials used in the construction of high mast flood lights must be strong enough to resist wind loads while also being durable and corrosion-resistant. Common materials for the mast include steel, aluminum, and composite materials. Steel is often preferred for its strength and durability, especially in areas with high wind loads. However, aluminum and composites may be used in certain applications where weight reduction is a priority.

Corrosion resistance is another important factor, particularly in coastal areas where saltwater exposure can accelerate material degradation. Galvanized steel or powder-coated materials are often used to enhance corrosion resistance and extend the lifespan of the high mast flood lights.

Mast Design and Construction

The design of the mast itself plays a critical role in resisting wind loads. Tapered masts, which gradually decrease in diameter from the base to the top, are commonly used in high mast flood light installations. This design provides greater strength at the base where the wind load is highest, while reducing the overall weight of the mast.

The mast must also be properly anchored to the ground to prevent it from being uprooted by strong winds. Deep foundations or reinforced concrete bases are often used to secure the mast and provide stability. In some cases, guy wires may be used to provide additional support, particularly for taller masts in high wind areas.

Mounting and Fixture Design

The way the flood lights are mounted on the mast can also influence wind load resistance. Adjustable mounts allow the lights to be oriented in a way that minimizes wind resistance, while fixed mounts provide greater stability but may be more exposed to wind forces. The fixtures themselves should be designed with wind resistance in mind, using aerodynamic shapes and materials that reduce wind load.

In some cases, engineers may opt for multiple smaller flood lights rather than a single large fixture. This approach can help distribute the wind load more evenly across the mast and reduce the overall wind resistance of the installation.

Wind Tunnel Testing

Wind tunnel testing is an important step in the design and validation of high mast flood lights. By simulating wind conditions in a controlled environment, engineers can assess how different wind speeds, angles, and conditions affect the wind load on the structure. Wind tunnel testing provides valuable data that can be used to optimize the design of the mast, fixtures, and mounts to ensure that they can withstand real-world wind conditions.

Benefits of Wind Tunnel Testing

Wind tunnel testing allows engineers to identify potential weaknesses in the design before the high mast flood lights are installed. By testing different shapes, materials, and configurations, engineers can determine the most effective design for resisting wind loads. This testing also helps ensure that the installation meets relevant safety standards and building codes, reducing the risk of failure in the field.

Application in Real-World Scenarios

In regions with high wind speeds, wind tunnel testing is often a mandatory part of the design process for high mast flood lights. The data obtained from these tests can be used to make informed decisions about material selection, mast height, and fixture design. This ensures that the final installation is capable of withstanding the wind conditions specific to the installation site.

Safety Standards and Regulations

Various safety standards and regulations govern the design and installation of high mast flood lights, particularly in relation to wind load. These standards ensure that the lighting systems are safe, reliable, and capable of withstanding environmental stresses.

International Standards

International standards, such as those set by the International Electrotechnical Commission (IEC) and the American Society of Civil Engineers (ASCE), provide guidelines for calculating wind load and designing structures to resist it. These standards take into account factors such as wind speed, height, and geographical location, providing a framework for engineers to design safe and reliable high mast flood lights.

Compliance and Certification

Compliance with these standards is often required by law, particularly in regions with high wind speeds or stringent safety regulations. Certification by recognized testing and certification bodies ensures that the high mast flood lights meet the necessary safety and performance requirements. This certification process often includes wind load testing, material analysis, and structural assessments to ensure that the installation is fit for purpose.

Maintenance and Inspection for Wind Load Resilience

Even after installation, maintaining the wind load resilience of high mast flood lights requires regular inspections and maintenance. Wind load factors can change over time due to wear and tear, environmental conditions, and material degradation. Regular maintenance helps ensure that the lighting system remains safe and functional.

Regular Inspections

Regular inspections should be conducted to assess the condition of the mast, fixtures, and mounting hardware. Inspections should focus on identifying signs of corrosion, material fatigue, and structural damage that could compromise the wind load resistance of the system. Any issues identified during inspections should be addressed promptly to prevent failures.

Maintenance Practices

Maintenance practices for high mast flood lights should include cleaning, tightening of bolts and connections, and the replacement of damaged or corroded components. In regions with high wind loads, additional maintenance may be required to ensure that the system remains secure and stable. This may include reinforcing connections, reapplying protective coatings, or even replacing the mast if necessary.

Long-Term Wind Load Management

Long-term management of wind load factors involves monitoring changes in wind conditions and adjusting the lighting system as needed. This may include upgrading the system to newer, more wind-resistant designs, or implementing additional support structures such as guy wires or bracing. By staying proactive in managing wind load factors, operators can extend the lifespan of the high mast flood lights and ensure their continued safe operation.

Conclusion

The effectiveness and safety of high mast flood lights are heavily influenced by wind load factors. By understanding and addressing these factors—such as wind angle, fixture design, mast height, and geographical location—engineers can ensure the structural integrity and long-term performance of these lighting systems. Regular maintenance, adherence to safety standards, and proactive management of wind load factors are crucial for preventing potential failures and ensuring the reliable operation of high mast flood lights in various environmental conditions.