Table of Contents

ToggleWhat is Pulse Width Modulation (PWM)?

Pulse Width Modulation (PWM) is a sophisticated technique used to encode the amplitude of a signal into the width of pulses. Essentially, PWM involves switching a signal on and off at a high frequency. The duration of the “on” time relative to the “off” time—known as the duty cycle—determines the average power delivered to a load. This method is widely utilized in digital circuits where precise control of power or signal intensity is crucial.

Understanding PWM Operation

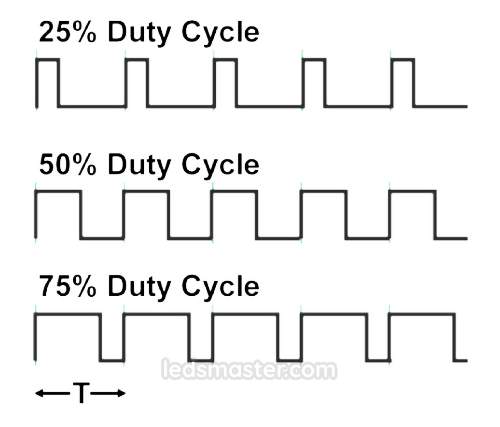

PWM operates by varying the duty cycle of a digital signal. The duty cycle represents the proportion of time a signal remains “on” compared to the total period of the signal. For example, in a PWM signal with a duty cycle of 70%, the signal is “on” for 70% of the time and “off” for the remaining 30%. This ratio is crucial because it directly impacts the average power delivered to the load. By adjusting the duty cycle, PWM effectively modulates the performance of devices, such as controlling the brightness of lights or regulating the speed of motors.

The Mechanics of PWM

In practical applications, PWM works by rapidly switching the signal between its “on” and “off” states. This high-frequency switching occurs so quickly that the human eye or other sensors perceive a steady output, rather than the flicker of the switching process. The effectiveness of PWM lies in its ability to finely tune the duty cycle, which in turn adjusts the average power delivered to the device. This ability to precisely control the duty cycle makes PWM a powerful tool in applications requiring detailed control over energy distribution.

PWM’s versatility extends across various fields, including lighting, motor control, and signal processing. In lighting systems, for instance, PWM dimmers use this technique to adjust light intensity with remarkable precision. By varying the pulse width of the PWM signal, these dimmers can provide smooth transitions between different brightness levels, which is essential for applications such as photography, stage lighting, and industrial settings where exact lighting conditions are required.

How Pulse Width Modulation Dimmer Works

Pulse Width Modulation (PWM) is a versatile and highly efficient technique used across a range of electronic applications to regulate the power delivered to various devices. By modulating the width of pulses in a signal, PWM controls the amount of energy transmitted to a load, making it a fundamental tool in electronics. This technique is especially valuable in lighting systems, where precision and efficiency are crucial. PWM dimmers, which harness the principles of PWM, offer a sophisticated method for adjusting the brightness of lights with remarkable accuracy.

Principles of PWM

To fully understand how PWM dimmers function, it’s important to delve into the underlying principles of PWM. PWM works by rapidly switching a signal between “on” and “off” states, with the duration of these states determining the average power delivered. This switching happens at such a high frequency that the human eye perceives a steady output, rather than the rapid flicker inherent in the switching process. The key to PWM’s effectiveness lies in its ability to adjust the duty cycle—the proportion of time the signal is on versus off—allowing precise control over the energy supplied to a device.

Mechanics of PWM Dimming

In the context of lighting, PWM dimmers modulate the brightness of lights by varying the pulse width of the PWM signal. The dimmer generates a series of pulses where the width of each pulse determines the average power reaching the light source. By adjusting this pulse width, PWM dimmers can control the intensity of the light with great precision, enabling smooth transitions between different brightness levels. This functionality is essential for applications where exact lighting conditions are required, such as in photography, stage lighting, and various industrial settings.

Benefits

Understanding the operation of PWM dimmers requires a closer look at both the technical details of PWM and the benefits it brings to lighting control. The PWM signal is typically generated by a microcontroller or a dedicated PWM controller, which determines the frequency and duty cycle of the signal. This signal is then used to control a switching device, like a transistor or MOSFET, which regulates the power delivered to the light. The ability to finely adjust the duty cycle allows for precise dimming control, maintaining efficiency and consistency in light output.

Technical Details of PWM Dimming

The technical operation of a Pulse Width Modulation (PWM) dimmer involves several key components and principles that work together to achieve precise control over lighting intensity. Understanding these components and how they interact provides insight into the effectiveness and versatility of PWM dimming technology.

Generation of the PWM Signal

The PWM signal, essential for dimming control, is generated at a frequency high enough to avoid noticeable flicker. Typically, this frequency can range from a few kilohertz (kHz) to several megahertz (MHz), depending on the specific requirements of the lighting system and the application. For general lighting purposes, frequencies are often in the range of 1 kHz to 20 kHz. Higher frequencies ensure that the rapid switching of the signal is imperceptible to the human eye, resulting in a steady and flicker-free light output.

Duty Cycle and Brightness Control

The duty cycle of the PWM signal is a fundamental aspect of dimming control. It represents the proportion of time the signal is “on” versus “off” during each cycle. For instance, a PWM signal with a 50% duty cycle means that the light is “on” for half of each cycle and “off” for the remaining half. This translates to a 50% brightness level. By adjusting the duty cycle, PWM dimmers can effectively control the average power delivered to the light source, thereby modulating its brightness. The granularity of this control is influenced by the resolution of the PWM signal; higher resolution allows for finer adjustments and more precise control over brightness levels.

Types of PWM Dimmers

PWM dimmers can be classified into two main types: analog and digital. Each type has its own set of characteristics and applications.

| Feature | Analog PWM Dimmers | Digital PWM Dimmers |

|---|---|---|

| Signal Generation | Uses analog components such as oscillators and modulators. | Utilizes microcontrollers or digital circuits. |

| Precision | Limited precision; less accurate control over brightness levels. | High precision; allows for fine control over brightness. |

| Flexibility | Less flexible; more fixed in functionality. | Highly flexible; supports advanced features and customization. |

| Noise and Interference | More susceptible to noise and interference. | Better noise resistance and stability. |

| Control Options | Basic control; manual adjustments are common. | Sophisticated control; includes remote and automated options. |

| Integration | Limited integration capabilities. | Can integrate with smart home systems and other digital controls. |

| Adaptability | Less adaptable to modern requirements. | Highly adaptable; suitable for modern lighting applications. |

| Stability | Less stable compared to digital alternatives. | Offers better stability and consistent performance. |

Integration and Advanced Features

In addition to basic dimming functions, digital PWM dimmers can integrate with various smart home technologies and automation systems. This integration allows for enhanced control options, such as remote operation via smartphone apps, voice control, and programmable lighting scenes. The ability to connect with other smart devices and systems makes digital PWM dimmers a versatile choice for contemporary lighting solutions.

Advantages of PWM Dimming

Pulse Width Modulation (PWM) dimming offers a range of significant advantages compared to other dimming methods. These benefits include efficiency, precision, and consistency, making PWM dimming a highly effective choice for various lighting applications.

Energy Efficiency

One of the most notable advantages of PWM dimming is its energy efficiency. Unlike traditional dimming methods, such as those that use resistive or capacitive techniques, PWM dimming controls brightness by adjusting the duty cycle of the signal rather than reducing the voltage. This means that PWM dimmers do not dissipate excess energy as heat. In contrast, resistive dimmers often convert unused energy into heat, leading to energy wastage and potential overheating. By avoiding this energy loss, PWM dimmers contribute to overall energy savings and improve the efficiency of the lighting system.

Precise Control

PWM dimming is renowned for its precise control capabilities. The technique adjusts brightness by varying the duty cycle of the PWM signal, allowing for highly granular adjustments. This high resolution enables smooth and accurate control over light intensity. Such precision is essential in scenarios where exact lighting conditions are crucial. For instance, in photography, stage lighting, or various industrial environments, precise control of brightness can significantly impact the quality of the output and the effectiveness of the lighting.

Maintained Color Temperature

Another significant benefit of PWM dimming is its ability to maintain consistent color temperature. Unlike some traditional dimming methods, which can alter the color output as the brightness level changes, PWM dimming ensures that the color quality of the light remains stable. This consistency is critical in settings where color accuracy is paramount, such as art galleries, design studios, or any environment where visual precision is necessary. Maintaining color temperature ensures that the light remains true to its intended hue and brightness, regardless of the dimming level.

Versatility and Compatibility

PWM dimmers are highly versatile and compatible with a wide range of light sources. This includes modern LED lights, as well as traditional fluorescent and incandescent bulbs. This compatibility makes PWM dimmers a popular choice for diverse lighting applications, from residential and commercial settings to specialized environments. The ability to work with different types of light sources allows for greater flexibility in designing and implementing lighting solutions.

Enhanced Performance and Longevity

PWM dimmers also contribute to the enhanced performance and longevity of light sources. By reducing the power supplied through rapid switching rather than continuous adjustment, PWM dimming can help reduce stress on the lighting components. This can lead to longer-lasting bulbs and reduced maintenance requirements. Additionally, the efficiency and precise control offered by PWM dimmers contribute to optimal performance across various lighting scenarios.

In summary, PWM dimming stands out for its efficiency, precision, and ability to maintain color temperature. Its compatibility with various light sources further underscores its versatility, making it a superior choice for both conventional and specialized lighting applications. Whether for energy savings, accurate brightness control, or consistent color quality, PWM dimming delivers substantial benefits across a broad range of uses.

Wide-Ranging Uses of PWM Dimming in Lighting

PWM dimming is a highly versatile technology used across a broad spectrum of applications, ranging from residential lighting to complex industrial processes. Its ability to provide precise control over light intensity makes it a popular choice in various settings, each with its unique requirements and challenges.

Residential Lighting Applications

In residential settings, PWM dimmers are commonly integrated into modern LED lighting systems. Homeowners appreciate the ease with which they can adjust the brightness of their lights, tailoring the ambiance in different rooms to suit various activities and moods. Whether it’s creating a cozy atmosphere in the living room, providing soft lighting in a bedroom, or adjusting brightness in a home office, PWM dimming offers a flexible and energy-efficient solution. The fine control provided by PWM dimming ensures that lighting levels can be adjusted to enhance comfort and reduce energy consumption, making it an essential feature in contemporary home design.

In residential settings, PWM dimmers are commonly integrated into modern LED lighting systems. Homeowners appreciate the ease with which they can adjust the brightness of their lights, tailoring the ambiance in different rooms to suit various activities and moods. Whether it’s creating a cozy atmosphere in the living room, providing soft lighting in a bedroom, or adjusting brightness in a home office, PWM dimming offers a flexible and energy-efficient solution. The fine control provided by PWM dimming ensures that lighting levels can be adjusted to enhance comfort and reduce energy consumption, making it an essential feature in contemporary home design.

Sports Lighting Applications

PWM dimming is also making its mark in sports lighting, where the ability to precisely control light intensity is crucial. Sports venues, such as football stadiums, tennis courts, and baseball fields, require lighting that can be adapted to different events, weather conditions, and even time of day. PWM dimming allows for dynamic adjustments, ensuring that athletes and spectators enjoy optimal visibility and comfort. For instance, PWM technology is used in venues like Wembley Stadium in London and Madison Square Garden in New York, where lighting needs to be both powerful and adaptable. Whether it’s illuminating the field for a night game or adjusting the lights for a concert, PWM dimming offers the flexibility needed for diverse sports and entertainment events.

PWM dimming is also making its mark in sports lighting, where the ability to precisely control light intensity is crucial. Sports venues, such as football stadiums, tennis courts, and baseball fields, require lighting that can be adapted to different events, weather conditions, and even time of day. PWM dimming allows for dynamic adjustments, ensuring that athletes and spectators enjoy optimal visibility and comfort. For instance, PWM technology is used in venues like Wembley Stadium in London and Madison Square Garden in New York, where lighting needs to be both powerful and adaptable. Whether it’s illuminating the field for a night game or adjusting the lights for a concert, PWM dimming offers the flexibility needed for diverse sports and entertainment events.

Commercial and Industrial Lighting Applications

In commercial and industrial settings, PWM dimming is employed in a variety of lighting applications, including stage lighting, photography, and architectural lighting. The precise control offered by PWM dimmers is particularly valuable in environments where lighting must be adjusted frequently and accurately. For example, in a commercial photography studio, PWM dimmers enable photographers to fine-tune the brightness of their lights to achieve the perfect shot. In architectural lighting, PWM dimming is used to highlight specific features of a building or space, creating visually stunning effects that enhance the overall aesthetic. Industrial venues such as factories, warehouses, and production facilities also benefit from PWM dimming, as it allows for efficient lighting management, reducing energy costs while maintaining optimal working conditions.

Automotive Lighting Applications

PWM dimming is widely utilized in automotive lighting, where it plays a key role in controlling the brightness of dashboard lights, interior lights, and headlights. The use of PWM dimmers in vehicles ensures that lighting can be adjusted to suit different driving conditions, enhancing both functionality and safety. For example, PWM dimming is used in the headlights of luxury cars like the BMW 7 Series and Mercedes-Benz S-Class, where it provides smooth transitions between different light levels, reducing glare and improving visibility. In addition to enhancing driver comfort, PWM dimming contributes to energy efficiency, helping to extend the life of automotive lighting systems.

Scientific and Medical Lighting Applications

In scientific and medical settings, PWM dimming is employed in equipment where precise control of light intensity is critical. Laboratory environments often require adjustable lighting for experiments, and PWM dimmers provide the necessary accuracy to ensure reliable results. For instance, in a microbiology lab, PWM dimming might be used to control the intensity of light in a culture chamber, where specific lighting conditions are required for the growth of microorganisms. Medical equipment, such as surgical lights and diagnostic devices, also relies on PWM dimming to provide consistent and controlled illumination, enhancing the accuracy of procedures and reducing eye strain for medical professionals.

Conclusion

Pulse Width Modulation dimming represents a sophisticated and efficient method of controlling lighting brightness. By adjusting the duty cycle of a rapidly switching signal, PWM dimmers offer precise control over light intensity, maintaining energy efficiency and color consistency. With applications spanning residential, commercial, and industrial settings, PWM dimming continues to be a valuable technology for various lighting needs. Understanding its principles and benefits highlights why PWM dimmers are increasingly favored in modern lighting solutions.